![]()

Ensuring our teams’ safety

Crescent Petroleum ensures that hazards inherent in its activities, ranging from production operations to drilling to major capital project construction to regular production operations, as well as infrastructure including IT, are subject to systematic identification, assessment, and control. This approach is fundamental to our safe operations. Information on the hazards, risks, and controls of operation is communicated to the workforce through inductions, training, written procedures, toolbox talks, awareness programmes, and regular safety meetings.

This approach is applied to all activities under our control, including activities by third-party contractors.

Our commitment to the UN SDGs:

| Our elevated safety standards illustrate our commitment to employees’ health and safety. | |

| We have consistently maintained a safe and decent work environment for our employees. |

2019 and 2020 Highlights

Operational and risk controls

Crescent Petroleum has adopted the International Oil and Gas Producers Association (IOGP)’s Life Saving Rules, embodied in its Rules for Staying Alive. These mandate the minimum controls expected to address the recognised highest hazard operational and construction activities.

The Rules for Staying Alive cover:

Ensuring our contractors uphold our standards

Contractors comprise a significant part of Crescent Petroleum’s workforce and play an important role in providing facilities, equipment, services, and labour to support our operations.

The company has an established contractor management process overseeing contractor prequalification, selection, monitoring, and performance review. Special attention is paid to contractors engaged in the highest-risk activities.

The contractors’ own HSSE&SP systems are assessed during the selection process to ensure that they are able to meet our strict standards, including a full review of HSSE&SP programmes, performance, and regulatory track record, including sustainability criteria. Bid evaluation includes a thorough assessment and verification of bid submissions, with evaluation outcomes integrated into overall bid selection criteria alongside commercial and technical assessments.

Crescent Petroleum monitors both its own and its contractors’ systems to ensure their continued effectiveness, and senior-level engagement with contractors ensures that expectations are clear and ongoing performance receives appropriate attention.

Land transport safety

Driving-related incidents are the single biggest cause of fatalities in the oil and gas industry, and Crescent Petroleum applies the guidance issued by the IOGP to reduce risks in this critical area.

Process safety

Crescent Petroleum uses the American Petroleum Institute (API) and IOGP guidance definition of process safety. Simply put, we manage the integrity of our facilities through good design, operations, and maintenance.

Process safety risks are assessed using recognised industry approaches such as hazard identification; hazard and operability review; technical safety assessments, including layers of protection analysis, safety integrity level analysis, and fire and explosion assessment; job safety analysis; and task-based risk assessment.

Safety teams define critical elements and establish appropriate operational, testing, and maintenance procedures for all critical systems.

Security

Crescent Petroleum has established effective security arrangements in its operations. The security plan provides appropriate protection for personnel and assets, and covers existing operations, remote well and rig locations, and personnel and materials movement. The security plan establishes layers of protection, covering organisation, procedural, and hardware control measures.

The security plan is based on risk and threat assessment provided by an independent security risk consultancy together with ongoing assessment and risk analysis by the internal security department. The assessment methodology assesses intent and capability of potential actors, as well as attractiveness of the assets, in determining the threat level on a five-point scale. The threat level is then used to determine appropriate levels of response measures, allowing for escalation or de-escalation should atmospherics and assessed threats change.

Regular monitoring of security incidents and intelligence takes place through a variety of means, including subscription services, private security provider reports, and local intelligence.

Delivering continuous improvement

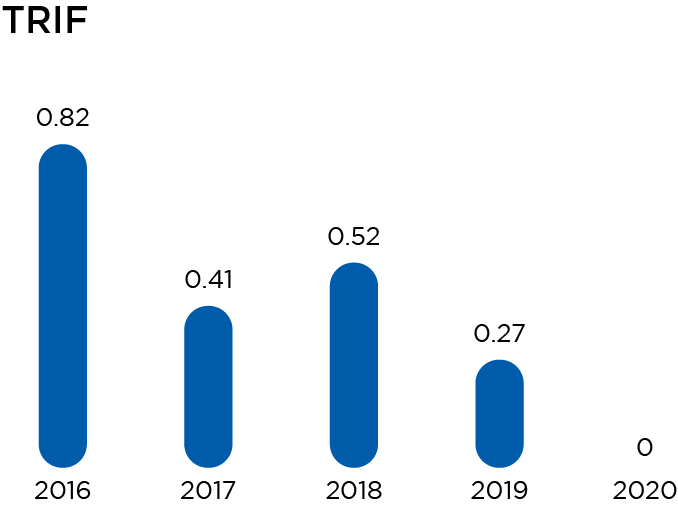

Crescent Petroleum saw a significant improvement in occupational injury performance in the KRI in 2019, with a 50 per cent reduction in Total Recordable Injury Frequency (TRIF), and zero LTI. This improved in 2020 with zero Recordable Injuries experienced through the year. In every injury case the injured parties have made full recoveries and the incidents were each subject to full investigations with appropriate remedial action. We believe that our focus on contractor management and hazard and risk awareness has positively affected the occupational safety results achieved.

Ongoing focus on operational integrity resulted in zero loss in primary containment incidents in our production operations in 2019 and 2020. Review and verification of multiple Safety Critical Elements, and continual optimisation of our inspection programme contributed to this result.

Additional control measures were introduced to further improve our land transport safety programme, which contributed to there being no significant motor vehicle accidents in 2019 and 2020.

Accelerating our digital transformation

In 2019 and 2020 we accelerated our ongoing digital transformation journey to improve process efficiency, transparency, and resilience. With the onset of the COVID-19 pandemic, our digital readiness enabled us to work seamlessly from home.

Our primary digital transformation initiatives have included the adoption of Microsoft Azure Windows Virtual Desktop for employees to securely access corporate data remotely. We have also decommissioned Skype for Business in favour of the more comprehensive business communication platform Microsoft Teams. We have trained our employees on the use of Microsoft Teams, other virtual conferencing programmes, electronic signatures, and PDF tools throughout 2020 to enable them to work from home effectively.

Moreover, we have enhanced our data analytics and visualisation capabilities to support a data-driven culture across the company and provide key decision-makers with business intelligence (BI) services. This entailed the introduction of an SQL analytics platform and of Microsoft Power BI, in addition to the development of interactive and immersive dashboard and analytics reports that offer actionable insights for decision-makers.

Finally, we have created a data warehouse to store outdated applications, or legacy systems, more efficiently. We have migrated all legacy applications data to Microsoft SQL Database, which enables us to avoid the licencing costs of such applications, and we created data reporting models to easily retrieve archived information.

Securing our networks

Protecting our corporate data from abuse, breaches, and theft is a priority of our IT Department. We have reinforced our data protection measures in 2019 and 2020 by adopting novel cybersecurity and network integrity solutions and continuing to raise awareness among our employees. We are also currently implementing the KnowBe4 platform to help us conduct more interactive trainings on Information Security Awareness.

Launching integrated ERP system

We focused on widening our digital transformation efforts to further safeguard our corporate data and simplify our processes throughout 2019 and 2020. Most significantly, we accelerated our digital transformation journey with the implementation of the SAP Enterprise Resource Planning (ERP) system for enhanced efficiency, accountability, planning, reporting, collaboration, productivity, and data security across our areas of operation in the UAE and the KRI.

We became the first company to implement SAP S/4HANA Oil and Gas Model Company 1809, a preconfigured process solution that prioritises industry best practices. We have achieved go-live in a record time of eight months, ahead of schedule and within budget, in early 2020.

The solution, which supersedes multiple application software and processes previously used in the business, simplifies and streamlines processes across drilling operations, plant maintenance, supply chain management, projects, funds management, and human resources functions. The SAP system provides integrated, detailed business information, and offers greater flexibility and mobility, in addition to eliminating paperwork and boosting overall efficiencies.

Digital transformation journey recognised at SAP Quality Awards 2020 – MENA

Crescent Petroleum is the Gold Winner of the Business Transformation ME South category at the SAP Quality Awards 2020 MENA.

A panel of independent jury and SAP senior executives conferred the award, deeming our ERP implementation to be the most successful one across all industry verticals in the region. Such a success stems from our commitment to the core values of “Enterprise” and “Courage”.

Our ERP system currently encompasses more than 300 apps for real-time and common-work centres functions. We will continue to introduce dashboards and mobility solutions for our maintenance team, as well as sensor-driven predictive maintenance capabilities. In the future, these applications will also stretch into hydrocarbon accounting and measurement to reinforce our sustainability efforts.